Poultry Farm Machinery

Leading Manufacturers, Exporters, Wholesaler, Trader and Distributor of 1 TPH Animal Feed Pellet Mill, 1 TPH Animal Pellet Feed Making Machines, 1 TPH Green Poultry Feed Making Machine, 100 Kg Poultry Feed Making Machine, 150-200 Kg HR Floating Fish Feed Machine, 200 Kg Cattle Feed Pellet Machine, 250 Kg Poultry Feed Mixer Machine, 300 Kg Automatic Pulverizer Grinding Machine, 400 Kg Industrial Cattle Feed Mixer, 45 Kg Stainless Steel Vibro Sifter, 500 Kg Animal Feed Making Plant, 500 Kg Cattle Feed Machine, 500 Kg Industrial Cattle Feed Mixer, 700 Kg Poultry Feed Machine, 700 Kg Poultry Feed Making Machine, Chili Grinding Machine, Floating Fish Feed Making Machine 50 Kgs Per Hrs, Screw Conveyors and Single Screw Extruder Fish Feed Making Machine from Kota.

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Type | Pellet Feed Mill |

| Production Capacity | 1 TPH |

| Voltage | 440V |

| Application | Poultry Farm |

| Power | 7.5 HP |

| Condition | New |

| Color | Blue |

| Dimensions (LxWxH) | 20x15x10 Feet |

Product Description

- Learn how to produce high-quality animal feed with our state-of-the-art pellet mill. Enhance nutrition and boost efficiency for your livestock.Unlock the secret to producing high-quality animal feed with our cutting-edge pellet mill. Boost your livestock's health and productivity today!Discover the best animal feed pellet mill for your farm today! Increase efficiency and quality of feed production with our state-of-the-art equipment.Discover how our high-quality animal feed pellet mill can revolutionize your feed production process. Increase efficiency and quality with our innovative technology today!Discover the top-quality animal feed pellet mill for efficient feed production. Increase productivity and ensure the health of your livestock with our innovative solution.Discover high-quality animal feed pellet mills to optimize your feed production. Increase efficiency and quality for healthier livestock

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Color | Grey |

| Voltage | 440V |

| Motor Power | 25 Hp |

| Capacity | 1 TPH |

| Automatic Grade | Semi Automatic |

| Material | Mild Steel |

| Die Ring Diameter | 320 mm |

Product Description

- Discover the top-quality animal pellet feed making machines for efficient and cost-effective production. Improve your feed processing process now!Discover how our top-quality animal pellet feed making machines can revolutionize your feed production process. Increase efficiency and quality today!Discover the top-quality animal pellet feed making machines for your farm. Increase productivity and efficiency with our advanced equipment. Choose the best for your livestock!Discover the best animal pellet feed making machines for your farm. Increase productivity and efficiency with top-quality equipment. Upgrade your feed production today!Discover the best animal pellet feed making machines for efficient and cost-effective feed production. Increase your output and save time with top-quality equipment.Discover the top-quality animal pellet feed making machines ideal for efficient feed production. Explore our range for high-performance equipment today!

| Business Type | Manufacturer, Supplier, Trader |

| Warranty | 1 Year,NONE |

| Frequency | 50 Hz |

| Capacity | 1 TPH |

| Voltage | 230 V |

| Automation Grade | Automatic |

| Power | 30 |

| Driven Type | Electric, Electric |

| Material | Mild Steel,MS AND SS |

| Motor Power | TOTAL 50 HP |

| Application | Cattle Feed Macking |

| Type | Feed Plant,FEED PELLET MACHINE |

| Country of Origin | India |

| Motor Power (H.P) | 55 HP |

| Brand Name | PRATIHAR ENTERPRISES |

| Size | 2 MM TO 8 MM |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

A 1 Ton Per Hour Poultry Feed Making Machine is a medium-capacity feed production system that can produce approximately 1,000 kg of poultry feed per hour. This type of machine is ideal for small to medium poultry farms and feed production businesses.

1 Ton Per Hour Poultry Feed Making Machine Overview ✅ What is It?

It is a complete poultry feed production line designed to manufacture balanced poultry feed at a capacity of 1 ton per hour. The system typically includes grinding, mixing, pelletizing, cooling, and packaging stages.

Main Components of the Plant

| Hammer Mill (Grinder) | Crushes raw materials into powder |

| Feed Mixer | Uniformly mixes all ingredients |

| Feed Pellet Machine | Compresses mixed feed into pellets |

| Pellet Cooler | Reduces temperature & moisture |

| Vibrating Sieve (optional) | Removes fines and oversized pellets |

| Packing Machine | Automatically bags the final feed |

| Conveyor System | Transfers material between machines |

-

Raw Material Grinding – Using a hammer mill

-

Feed Mixing – Uniform blending of all ingredients

-

Pelletizing – Forming the mixed feed into pellets

-

Cooling – Hardening the pellets and reducing moisture

-

Screening (optional) – Ensuring uniform pellet size

-

Packaging – Bagging the finished feed for storage or sale

| Capacity | 1 Ton per Hour |

| Power Requirement | 50 – 80 kW total |

| Pellet Size | 2 mm to 8 mm |

| Mixing Time | 5 – 8 minutes per batch |

| Material Used | Mild Steel or Stainless Steel |

| Operation Type |

Semi-automatic or Automatic |

Advantages

-

Suitable for small to medium-scale poultry feed plants

-

Produces consistent and high-quality poultry feed

-

Customizable feed formulas

-

Can make broiler feed, layer feed, chick feed, etc.

-

Moderate power consumption and low labor requirement

-

Easy to install and maintain

Raw Materials Used

-

Maize (Corn)

-

Soybean Meal

-

Wheat Bran

-

Rice Bran

-

Fish Meal

-

Bone Meal

-

Vitamins and Minerals

-

Salt, Oil, etc.

| Basic Semi-Automatic Line | ₹8 lakh – ₹15 lakh |

| Fully Automatic Line | ₹15 lakh – ₹25 lakh+ |

(Prices depend on automation level, material quality, and brand)

| Business Type | Manufacturer, Supplier, Trader |

| Material | Mild Steel |

| Driven Type | Electric |

| Motor Power | 30 HP |

| Automation Grade | Semi Automatic |

| Voltage | 240 V |

| Capacity | 100 Kg/hr |

| Country of Origin | India |

| Application | Grinding |

| Phase | Single Phase |

Product Description

- Discover the ultimate solution for producing high-quality poultry feed with our advanced poultry feed making machine. Increase efficiency and quality effortlessly!Discover the ultimate solution for producing high-quality poultry feed with our advanced poultry feed making machine. Increase efficiency and quality effortlessly!Discover how our innovative poultry feed making machine can streamline your operations and boost productivity. Invest in quality equipment for happier, healthier birds!Discover how our advanced poultry feed making machine can revolutionize your farming operations. Increase efficiency and quality with our innovative solution today!"Discover the top-rated poultry feed making machine for efficient and high-quality feed production. Increase productivity and profitability with our advanced equipment!" our advanced equipment ensures efficient and cost-effective feed production for your poultry farm.

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | PRATIHAR ENTERPRISES |

| Material | Mild Steel |

| Color | Grey |

| Condition | New |

| Automatic Grade | Semi Automatic |

| Power | 15-20kw,10 HP |

| Certification | ISO 9001:2008 |

| Voltage | 440V |

| Weight | 1-5 Ton |

| Warranty | 1 Year |

| Country of Origin | India |

| Frequency | 50 Hz |

| Material To Be Extruded | Multigrain |

| After-Sales Service Provided | YES |

| Screw Design | INDIAN |

| PRODUCTION | 100 KGS PER HRS |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

| Packaging Details | depended on transport and buyer scope . |

A floating fish feed extruder is a machine that processes raw materials into fish feed pellets that float on water for extended periods. Floating pellets are ideal because they help fish farmers monitor the fish’s feeding behavior and reduce feed waste.

✅ Key Features

-

Produces Floating Pellets: Pellets can float for 12-24 hours.

-

Adjustable Size: Pellet size can be adjusted from 0.5 mm to 15 mm.

-

Temperature & Pressure Control: Ensures proper cooking and extrusion.

-

Single-screw or Twin-screw Types: Twin-screw models offer higher capacity and versatility.

-

Electric or Diesel Operated: Based on the model.

⚙️ Working Principle

-

Mixing: Raw materials like fish meal, corn, soybean, vitamins, etc., are mixed.

-

Extrusion: The mixture is fed into the extruder, where it is cooked by high temperature and pressure.

-

Shaping: The screw forces the material through a die, shaping it into pellets.

-

Cutting: Rotating knives cut the pellets to desired sizes.

-

Drying & Cooling: Pellets are dried to remove moisture and cooled to harden.

-

Flavoring (optional): Oils or attractants can be sprayed on the cooled pellets.

🛠️ Technical Specifications (Example)

| Capacity | 50 kg/h to 1000 kg/h |

| Motor Power | 15 kW to 160 kW |

| Pellet Size | 0.5 mm to 15 mm |

| Material | Stainless Steel/Carbon Steel |

| Floating Time | 12-24 hours |

| Operation | Manual or Automatic |

👍 Advantages

-

High floating durability of feed.

-

Easy to digest pellets.

-

Reduces feed waste.

-

Can produce sinking feed as well with adjustment.

-

Energy efficient and high output.

🔧 Common Applications

-

Fish farms (catfish, tilapia, carp, etc.)

-

Shrimp farms

-

Pet food processing

-

Small-scale or commercial aquaculture

| Business Type | Manufacturer, Supplier, Trader |

| Material | Iron |

| Driven Type | Electric |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 5 HP |

| Voltage | 220V |

| Type | Cattle Feed Machine |

| Warranty | 1year |

| Country of Origin | India |

| Die Ring Diameter | 650 mm |

| Capacity | 200 Kg/Hr |

It is a production system that processes raw agricultural materials like grains, oilseeds, and additives into balanced feed for animals. The feed can be produced in various forms like pellets, mash, crumbles, or floating feed.

🏭 Types of Animal Feed Produced-

Cattle Feed

-

Poultry Feed (Broiler, Layer)

-

Fish Feed (Floating and Sinking)

-

Goat/Sheep Feed

-

Pet Food

-

Pig Feed

| Hammer Mill | Grinding raw materials |

| Feed Mixer | Mixing different feed ingredients |

| Feed Pellet Machine / Extruder | Forming feed into pellets |

| Dryer / Cooler | Reducing moisture in feed pellets |

| Crumbler | Breaking pellets into smaller sizes |

| Packing Machine | Automatic packaging of final feed |

| Conveyor Belts | Material handling |

-

Raw Material Receiving

-

Grinding (Hammer Mill)

-

Mixing (Feed Mixer)

-

Pelletizing (Feed Pellet Machine)

-

Drying and Cooling

-

Screening and Crumbling (if needed)

-

Packing and Storage

-

High production efficiency

-

Cost-effective feed production

-

Consistent feed quality

-

Customizable formulations for different animals

-

Reduces feed wastage

-

Enables local feed production, reducing dependency on external suppliers

| Small-Scale Plant | 500 kg to 1 ton/day |

| Medium-Scale Plant | 1 ton to 10 tons/day |

| Large-Scale Plant | 10 tons to 100+ tons/day |

| Small Plant | ₹5 lakh to ₹15 lakh |

| Medium Plant | ₹15 lakh to ₹50 lakh |

| Large Plant | ₹50 lakh to ₹5 crore+ |

(Costs depend on automation, capacity, and location.)

📦 Raw Materials Used

-

Maize, Soybean Meal, Rice Bran

-

Wheat Bran, Fish Meal, Bone Meal

-

Molasses, Vitamins, Minerals, Additives

-

Oil, Salt, etc.

| Business Type | Manufacturer, Supplier, Trader |

| Material | Mild Steel,MS AND SS |

| Driven Type | Electric, Electric |

| Motor Power | 3 Hp |

| Automation Grade | Automatic |

| Voltage | 440 V |

| Capacity | 200 Kg/hour, 250 Kg |

| Frequency | 50 Hz |

| Warranty | 5 Years,ONE TIME |

| Country of Origin | India |

| Type | FEED MIXER |

| Brand Name | PRATIHAR ENTERPRISES |

| Color | OUR PATERN |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

A poultry feed mixer is a machine designed to blend multiple feed ingredients into a consistent and homogenous mixture. This ensures that every portion of the feed contains the same amount of nutrients, which is critical for the health and growth of poultry like broilers and layers.

Types of Poultry Feed Mixers-

Horizontal Feed Mixer

-

U-shaped mixing chamber with rotating paddles or blades.

-

Fast and uniform mixing.

-

Suitable for large batches.

-

-

Vertical Feed Mixer

-

Vertical screw or auger to lift and mix feed materials.

-

More economical.

-

Suitable for small to medium scale plants.

-

-

Ribbon Blender

-

Spiral-shaped ribbons mix the materials.

-

Ideal for delicate blending.

-

-

Double Shaft Paddle Mixer

-

High-speed and high-efficiency mixing.

-

Suitable for commercial plants requiring faster batch cycles.

-

-

The mixer takes raw materials from the feed hopper.

-

The blades or paddles inside the mixer rotate, moving the materials in multiple directions.

-

Within 2 to 10 minutes, the materials are uniformly blended.

-

The mixed feed is then discharged for pelletizing or packing.

| Capacity | 250 kg/batch to 2 tons/batch |

| Power | 3 kW to 15 kW |

| Mixing Time | 5-10 minutes per batch |

| Mixing Accuracy | CV ≤ 5% |

| Material | Mild Steel or Stainless Steel |

| Business Type | Manufacturer, Supplier, Trader |

| Capacity | 300 Kg/hr |

| Phase | three phase |

| Brand Name | pratihar enterprises |

| Material | ms and ss |

| Automatic Grade | Automatic |

| Power | 1-3kw |

| Certification | ISO 9001:2008 |

| Voltage | 440V |

| Weight | 300-400kg |

| Warranty | none |

| After-Sales Service Provided | yes |

| Country of Origin | India |

| Motor Power | 5 |

| Application | feed grade |

Product Description

\\n- \\n

- Discover the best poultry feed making machine that ensures efficient and high-quality feed production for your farm. Invest in top-notch equipment for optimal results!Discover how our advanced poultry feed making machine maximizes efficiency and quality in your poultry farm. Streamline your operations today!Discover the best poultry feed making machine for your farm. Increase efficiency and quality with our top-of-the-line equipment. Start optimizing your poultry feed production today!Discover the best poultry feed making machine for your farm. Increase efficiency and quality of your feed production with our top-rated equipment.Discover the efficient and reliable poultry feed making machine that ensures top-quality feed for your poultry farm. Increase productivity and save time with this innovative equipment!Our poultry feed making machine ensures efficiency and quality in every batch. Discover more now! \\n

| Business Type | Manufacturer, Supplier, Trader |

| Color | Blue |

| Condition | New |

| Power | 5 HP |

| Type | Food Mixer |

| Country of Origin | India |

| Power Source | Electric |

| Capacity | 400 Kg |

| Dimensions (LxWxH) | 4x2x6 Feet |

| Mixing Period | 2 Minutes |

A poultry feed mixer is a machine designed to blend multiple feed ingredients into a consistent and homogenous mixture. This ensures that every portion of the feed contains the same amount of nutrients, which is critical for the health and growth of poultry like broilers and layers.

Types of Poultry Feed Mixers

-

Horizontal Feed Mixer

-

U-shaped mixing chamber with rotating paddles or blades.

-

Fast and uniform mixing.

-

Suitable for large batches.

-

-

Vertical Feed Mixer

-

Vertical screw or auger to lift and mix feed materials.

-

More economical.

-

Suitable for small to medium scale plants.

-

-

Ribbon Blender

-

Spiral-shaped ribbons mix the materials.

-

Ideal for delicate blending.

-

-

Double Shaft Paddle Mixer

-

High-speed and high-efficiency mixing.

-

Suitable for commercial plants requiring faster batch cycles.

-

Working Principle

-

The mixer takes raw materials from the feed hopper.

-

The blades or paddles inside the mixer rotate, moving the materials in multiple directions.

-

Within 2 to 10 minutes, the materials are uniformly blended.

-

The mixed feed is then discharged for pelletizing or packing.

| Capacity | 250 kg/batch to 2 tons/batch |

| Power | 3 kW to 15 kW |

| Mixing Time | 5-10 minutes per batch |

| Mixing Accuracy | CV ≤ 5% |

| Material |

Mild Steel or Stainless Steel |

| Business Type | Manufacturer, Supplier, Trader |

| Production Capacity | 45 Kg/hr |

| Country of Origin | India |

| Phase | Single Phase |

| Voltage | 440V |

| Operating Type | Semi Automatic |

| Power | 3 HP |

| Condition | New |

| Driven Type | Electric |

| Finishing | Paint Coated |

| Material | Stainless Steel,Ms and Ss |

| Type | circlie type |

| Brand Name | Pratihar Enterprises |

| Warranty | As per party demand |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

Product Description

Pratihar Enterprises

Discover the efficiency of our stainless steel vibro sifter

Perfect for precise screening & separating of materials in various industries.

Upgrade your processes today!"Efficiently sift your materials with our high-quality stainless steel vibro sifter.

Perfect for precise screening and separating particles. Upgrade your sifting process today!Looking for a high-quality stainless steel vibro sifter?

Our sifter is durable, efficient, and perfect for your industrial needs.

Find out more now!Discover the ultimate solution for precise particle separation with our stainless steel vibro sifter.

Improve efficiency and quality in your product manufacturing process today!Discover the efficiency and durability of our stainless steel vibro sifter

the perfect solution for your precision sieving needs.

Upgrade to top-notch quality today!"Discover the efficient and durable stainless steel vibro sifter for precise particle separation.

Enhance your production process with our high-quality sifting solution.

| Business Type | Manufacturer, Supplier, Trader |

| Condition | New |

| Automatic Grade | Fully Automatic |

| Power | 20 HP |

| Country of Origin | India |

| Brand Name | PRATIHAR ENTERPRISES |

| Color | Grey, Light White |

| Certification | Iso 9001:2008 |

| Application | Making Cattle Feed |

| Driven Type | Electric |

| Capacity | 500 Kg/hr |

| Material | Mild Steel |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

An animal feed making plant is a facility that manufactures feed products for livestock, poultry, fish, and other animals. These plants can vary in size from small-scale units to large industrial factories, depending on the type and volume of feed production required.

📄 Animal Feed Making Plant: Overview ✅ What is an Animal Feed Making Plant?

It is a production system that processes raw agricultural materials like grains, oilseeds, and additives into balanced feed for animals. The feed can be produced in various forms like pellets, mash, crumbles, or floating feed.

🏭 Types of Animal Feed Produced

-

Cattle Feed

-

Poultry Feed (Broiler, Layer)

-

Fish Feed (Floating and Sinking)

-

Goat/Sheep Feed

-

Pet Food

-

Pig Feed

| Hammer Mill | Grinding raw materials |

| Feed Mixer | Mixing different feed ingredients |

| Feed Pellet Machine / Extruder | Forming feed into pellets |

| Dryer / Cooler | Reducing moisture in feed pellets |

| Crumbler | Breaking pellets into smaller sizes |

| Packing Machine | Automatic packaging of final feed |

| Conveyor Belts | Material handling |

| Business Type | Manufacturer, Supplier, Trader |

| Material | Mild Steel |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Voltage | 440V |

| Warranty | 1year |

| Country of Origin | India |

| Capacity | 500 Kg/hr |

| Type | Cattle Feed Machine |

Product Description

- Discover the best cattle feed machine for optimal livestock nutrition. Increase efficiency and output on your farm with our top-of-the-line equipment."Discover the top-quality cattle feed machine to boost your livestock's nutrition and growth. Invest in our reliable and efficient equipment today!""Discover the best cattle feed machine for efficient livestock farming. Choose quality, durability, and performance for your feed processing needs now!"Discover the best cattle feed machine for your farm. Increase efficiency and streamline your operation with our top-quality equipment."Find the best cattle feed machine for your farm! Discover top quality, efficient, and affordable solutions to streamline your livestock feed production process.""Discover the best cattle feed machine for your farm with our top-quality products. Maximize efficiency and productivity with our innovative technology!

| Business Type | Manufacturer, Supplier, Trader |

| Color | Blue |

| Condition | New |

| Power | 5 HP |

| Power Source | Electric |

| Voltage | 415 V |

| Type | Catted Feed mixer |

| Country of Origin | India |

| Driven Type | Electric |

| Dimensions (LxWxH) | 4x2x6 Feet |

| Material | Mild Steel |

| Capacity | 500 Kg |

Product Description

\\n- \\n

- Our top-quality cattle feed mixers are designed to efficiently blend feed ingredients, ensuring optimal nutrition for your livestock. Find the perfect solution for your farm today!Our top-of-the-line equipment ensures efficient mixing for optimal nutrition. Invest in quality for healthier livestock.Find the perfect cattle feed mixer for your farm needs. Our high-quality and efficient mixers ensure optimal nutrition for your livestock.Our top-rated mixer is designed to efficiently blend different feed ingredients for your livestock\\\'s optimal nutrition. Shop now!Our top-notch products ensure efficient and uniform mixing for your livestock\\\'s nutrition needs. Boost efficiency and quality today! \\n

| Business Type | Manufacturer, Supplier, Trader |

| Voltage | 240 V |

| Country of Origin | India |

| Weight | 200 Kg |

| Capacity | 700 Kg/ Per Hour |

| Automation Grade | Semi Automatic |

| Driven Type | Electric |

| Finish | Paint Coated |

Product Description

- Discover the top-rated poultry feed machine designed for efficiency and cost-effectiveness. Streamline your operations with our cutting-edge technology today!" discover top-quality options designed for efficiency and performance here!"Discover the top-rated poultry feed machine designed for efficiency and cost-effectiveness. Streamline your operations with our cutting-edge technology today!""Discover top-quality poultry feed machines for your farm - boost efficiency & productivity effortlessly. Find the best feed solution now!"Discover the best poultry feed machine for your farm. Increase efficiency and quality of feed production with our top-of-the-line equipment."Discover top-quality poultry feed machines for your farm - boost efficiency & productivity effortlessly. Find the best feed solution now!"

| Business Type | Manufacturer, Supplier, Trader |

| Country of Origin | India |

| Frequency | 50 Hz |

| Capacity | 700 Kg/Hr |

| Automation Grade | Automatic |

| Motor Power | 3 HP |

| Driven Type | Electric |

| Material | Mild Steel |

| Brand Name | pratihar enterprises |

| Payment Terms | Other |

| Delivery Time | 7 days |

A small-size poultry feed machine is a compact unit used to make poultry feed pellets (or mash) from raw materials like maize, soybean meal, rice bran, fish meal, etc. It's ideal for small farms, home use, or small-scale feed businesses.

ypes of Small Poultry Feed Machines:

| Flat Die Pellet Mill | 50–800 kg/hour | Best for making small batches of feed pellets |

| Mash Feed Mixer | 100–1000 kg/hour | Mixes ingredients into uniform mash feed |

| Mini Feed Plant | 200–1000 kg/hour | Includes grinder, mixer, and pelletizer in one unit |

| Business Type | Manufacturer, Supplier, Trader |

| Production Capacity | 200 Kg/hr |

| Country of Origin | India |

| Voltage | 440V |

| Automatic Grade | Automatic |

| Material | Mild Steel |

| Power Consumption | 2 Kwh |

| Usage/Application | Chili Grinding |

A Chili Grinding Machine is a specialized equipment used to grind dried chilies into chili powder or chili paste. It is commonly used in spice processing plants, food factories, and commercial kitchens.

Types of Chili Grinding Machines

-

Hammer Mill Type

-

Uses high-speed rotating hammers to crush and grind chili.

-

Suitable for coarse to medium fine powder.

-

-

Pin Mill Type

-

Uses high-speed pins for ultra-fine grinding.

-

Produces very fine chili powder.

-

-

Pulverizer Type

-

Compact design for continuous chili grinding.

-

Suitable for small to medium scale units.

-

-

Chili Paste Grinder (Wet Grinder)

-

Used for making chili paste or sauce.

-

Uses stone or stainless steel grinding wheels.

-

-

Cryogenic Chili Grinder

-

Uses liquid nitrogen to prevent heat generation.

-

Best for preserving color and flavor.

-

| Business Type | Manufacturer, Supplier, Trader |

| Brand Name | PRATIHAR ENTERPRISES, INDIAN BRAND |

| Color | Light White |

| Condition | New |

| Automatic Grade | Automatic,Fully Automatic,Manual,Semi Automatic |

| Power | 9-12kw,7.5 Hp |

| Certification | ISO 9001:2008 |

| Voltage | 440V |

| Country of Origin | India |

| Material | MS AND SS |

| Application | Industrial |

| Driven Type | Electric |

| Features | BEST MACHINE FOR FLOTING FISH FEED |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

A floating fish feed extruder is a machine that processes raw materials into fish feed pellets that float on water for extended periods. Floating pellets are ideal because they help fish farmers monitor the fish’s feeding behavior and reduce feed waste.

Key Features

-

Produces Floating Pellets: Pellets can float for 12-24 hours.

-

Adjustable Size: Pellet size can be adjusted from 0.5 mm to 15 mm.

-

Temperature & Pressure Control: Ensures proper cooking and extrusion.

-

Single-screw or Twin-screw Types: Twin-screw models offer higher capacity and versatility.

Working Principle

-

Mixing: Raw materials like fish meal, corn, soybean, vitamins, etc., are mixed.

-

Extrusion: The mixture is fed into the extruder, where it is cooked by high temperature and pressure.

-

Shaping: The screw forces the material through a die, shaping it into pellets.

-

Cutting: Rotating knives cut the pellets to desired sizes.

-

Drying & Cooling: Pellets are dried to remove moisture and cooled to harden.

-

Flavoring (optional): Oils or attractants can be sprayed on the cooled pellets

Technical Specifications (Example)

| Capacity | 50 kg/h to 1000 kg/h |

| Motor Power | 15 kW to 160 kW |

| Pellet Size | 0.5 mm to 15 mm |

| Material | Stainless Steel/Carbon Steel |

| Floating Time | 12-24 hours |

| Operation | Manual or Automatic |

| Business Type | Manufacturer, Supplier, Trader |

| Motor Power | 3 HP |

| Country of Origin | India |

| Capacity | 1000 Kg Per Hrs |

| Driven Type | Electric |

| Material | MS,Mild Steel |

| Brand Name | PRATIHAR ENTERPRISES |

| Application | A point to b point material shifter |

| Conveyor Length | 8 Meter |

| Warranty | 1year |

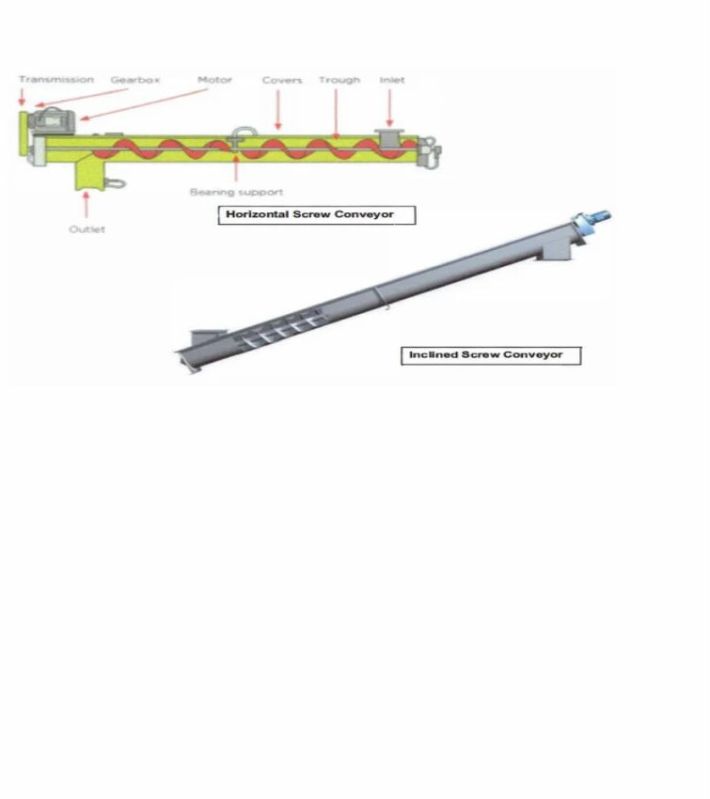

A Screw Conveyor (also called an auger conveyor) is a mechanical transport system used to move materials like grains, powders, pellets, and semi-solid substances through a rotating screw shaft inside a tube or trough.

\\n

\\nWorking Principle\\n

\\n

- \\n

- \\n

Rotating Screw Shaft: As the shaft rotates, the screw blade pushes the material forward.

\\n

\\n

- \\n

Inclination or Horizontal Movement: The conveyor can be set at various angles depending on the application.

\\n

\\n

- \\n

Controlled Discharge: Material can be discharged at specific points along the conveyor.

\\n

\\n

\\nTypes of Screw Conveyors\\n

\\n

| Horizontal Screw Conveyor | Most common, for level transport |

| Inclined Screw Conveyor | Moves materials to higher levels |

| Vertical Screw Conveyor | Transports materials vertically |

| Shaftless Screw Conveyor | Ideal for sticky or wet materials |

| Flexible Screw Conveyor | Can bend to fit tight spaces |

\\n

| Capacity | 500 kg/hr to 50 tons/hr |

| Screw Diameter | 100 mm to 500 mm |

| Length | 1 meter to 30 meters |

| Material | Mild Steel, Stainless Steel |

| Power Requirement | 1 HP to 20 HP |

| Operation Type | Manual, Semi-auto, Automatic |

\\n

\\n

\\n

| Business Type | Manufacturer, Supplier, Trader |

| Warrenty | Buyer Scope |

| Warranty | 1 Year |

| Weight | 1-5 Ton |

| Type | Fish Feed Making Machine |

| Certification | ISO 9001:2008 |

| Color | Grey |

| Brand Name | PRATIHAR ENTERPRISES |

| Material | Mild Steel |

| Condition | New |

| Automatic Grade | Automatic |

| Power | 9-12kw, 7.5 hp |

| Voltage | 440V |

| Country of Origin | India |

| Capacity | 500 Kg/hr |

| Features | Single Screw Extruder |

| Payment Terms | Other |

| Delivery Time | 7 DAYS AFTER FULL PAYMENT |

A floating fish feed extruder is a machine that processes raw materials into fish feed pellets that float on water for extended periods. Floating pellets are ideal because they help fish farmers monitor the fish’s feeding behavior and reduce feed waste.

\\n\\n✅ Key Features\\n

- \\n

- \\n

Produces Floating Pellets: Pellets can float for 12-24 hours.

\\n

\\n

- \\n

Adjustable Size: Pellet size can be adjusted from 0.5 mm to 15 mm.

\\n

\\n

- \\n

Temperature & Pressure Control: Ensures proper cooking and extrusion.

\\n

\\n

- \\n

Single-screw or Twin-screw Types: Twin-screw models offer higher capacity and versatility.

\\n

\\n

- \\n

Electric or Diesel Operated: Based on the model.

\\n

\\n

\\n\\n⚙️ Working Principle\\n

- \\n

- \\n

Mixing: Raw materials like fish meal, corn, soybean, vitamins, etc., are mixed.

\\n

\\n

- \\n

Extrusion: The mixture is fed into the extruder, where it is cooked by high temperature and pressure.

\\n

\\n

- \\n

Shaping: The screw forces the material through a die, shaping it into pellets.

\\n

\\n

- \\n

Cutting: Rotating knives cut the pellets to desired sizes.

\\n

\\n

- \\n

Drying & Cooling: Pellets are dried to remove moisture and cooled to harden.

\\n

\\n

- \\n

Flavoring (optional): Oils or attractants can be sprayed on the cooled pellets.

\\n

\\n

\\n🛠️ Technical Specifications (Example)\\n

| Capacity | 50 kg/h to 1000 kg/h |

| Motor Power | 15 kW to 160 kW |

| Pellet Size | 0.5 mm to 15 mm |

| Material | Stainless Steel/Carbon Steel |

| Floating Time | 12-24 hours |

| Operation | Manual or Automatic |

\\n\\n👍 Advantages\\n

- \\n

- \\n

High floating durability of feed.

\\n

\\n

- \\n

Easy to digest pellets.

\\n

\\n

- \\n

Reduces feed waste.

\\n

\\n

- \\n

Can produce sinking feed as well with adjustment.

\\n

\\n

- \\n

Energy efficient and high output.

\\n

\\n

\\n\\n🔧 Common Applications\\n

\\n

- \\n

- \\n

Fish farms (catfish, tilapia, carp, etc.)

\\n

\\n

- \\n

Shrimp farms

\\n

\\n

- \\n

Pet food processing

\\n

\\n

- \\n

Small-scale or commercial aquaculture

\\n

\\n